DIY Jaga Dynamic Boost Hybrid (DBE/DBH)

(Updated: )

I have Jaga radiators in my home, which are of the type hot-water baseboard (wikipedia.org) making them great low-thermal momentum, high power density radiators, especially compared to (jaga.com) panel radiators (wikipedia.org). In this article I build my own temperature-controlled fans on top of these to increase the power and reduce heating lag even more. Cost is ~60€ per 70cm unit with 7 fans, compared to 300€ for Jaga’s version and only 3 fans for Speedcomfort’s version.

Contents

Introduction ¶

Jaga sells ready-made fan modules called DBH (jaga.com) (Dynamic Boost Hybrid), which replaces the older DBE (Dynamic Boos Effect) modules. These come with a control and sensing unit, but are fairly expensive at ~300€ per meter. Alternatively there’s a company called Speedcomfort (speedcomfort.com) which make their own version, but they’re more aimed at panel radiators instead of the Jaga baseboard radiators, and only have 3 fans which means it’s louder or has less airflow.

Since I like the challenge and learning, I decided to make these myself, greatly inspired by the Gathering of Tweakers forum thread (tweakers.net) on this topic.

Requirements ¶

- 20 year lifetime @ 200 days heating per year

- @ 10 switches per day: >40 000 switches (ideal: >100k)

- @ 10 hours per day (=2000 hr/yr): > 40k hrs MTBF (ideal: >100k hrs)

- <5 €/yr per radiator running cost

- @ 0.25 €/kWh: <10W per radiator

- Double inflow-outflow ∆T versus no fans

- Silent, cannot hear when reading on couch

TL;DR - instructions for the impatient ¶

- Prepare aluminium frame

- Mark out fan holes with the fans in place (e.g. using a screw to scratch in the aluminium)

- Drill 5mm holes to mount the fans (needs to be somewhat precise)

- Saw out approximate fan blade area (to have unobstructed airflow)

- Drill holes in the side wall of the frame to fix the wires on

- Mount & connect the fans

- Mount the fans in the frame using supplied screws or M4 bolts

- Wrap the cable around the fan to prevent dangling

- Connect the cable to the essential molex fan plug splitter (hardwarewebwinkel.nl)

- Fix the cables to the hole in the side-wall drilled previously

- Make the controller, connect power

- Take a ~15cm piece of aluminium profile to mount the step-down converter (tinytronics.nl) and power supply (tweakers.net)

- Mount the DC jack connector (tinytronics.nl) to connect the thermostat switch (speedcomfort.nl)

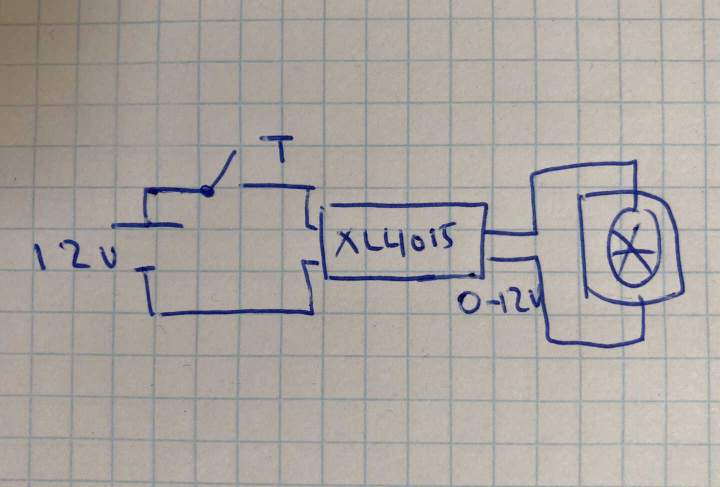

- Use the switch to break the positive polarity from the power supply, such that the step-down converter is not connected to live power when not operating.

- N.B. I mounted the controller + power supply away from the radiator (because of space and splash risk), such that I have 2 double-polarity cables running from the control unit to the radiator: 1 is for the thermostat switch, the second is for the 12-V power.

- Make support structure & installing

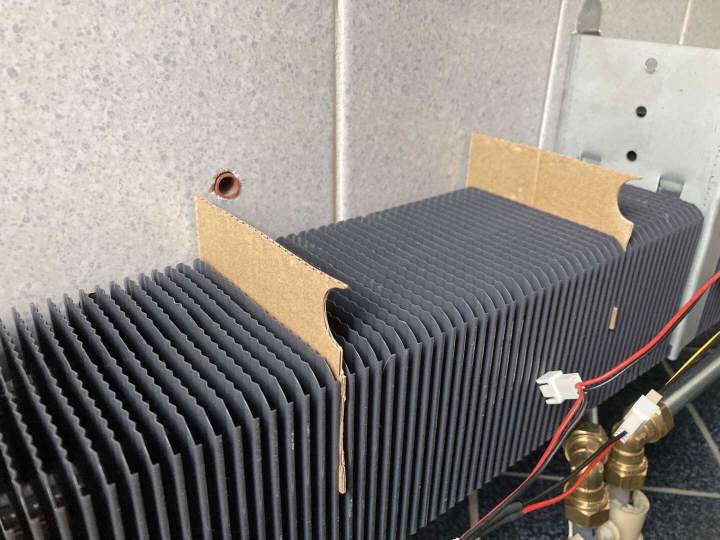

- To reduce noise slightly, I made a spacer between the radiator and fan out of cardboard.

- Simply cut to shape using scissors.

- Place in between fans to minimize airflow interference.

- Connect & power-up

Hardware and design ¶

This is most of the hardware required to make the DIY DBE fan arrays. Power supply not shown.

Bill of Materials ¶

For 2x 70 cm fan arrays, suitable for a 160cm Jaga radiator:

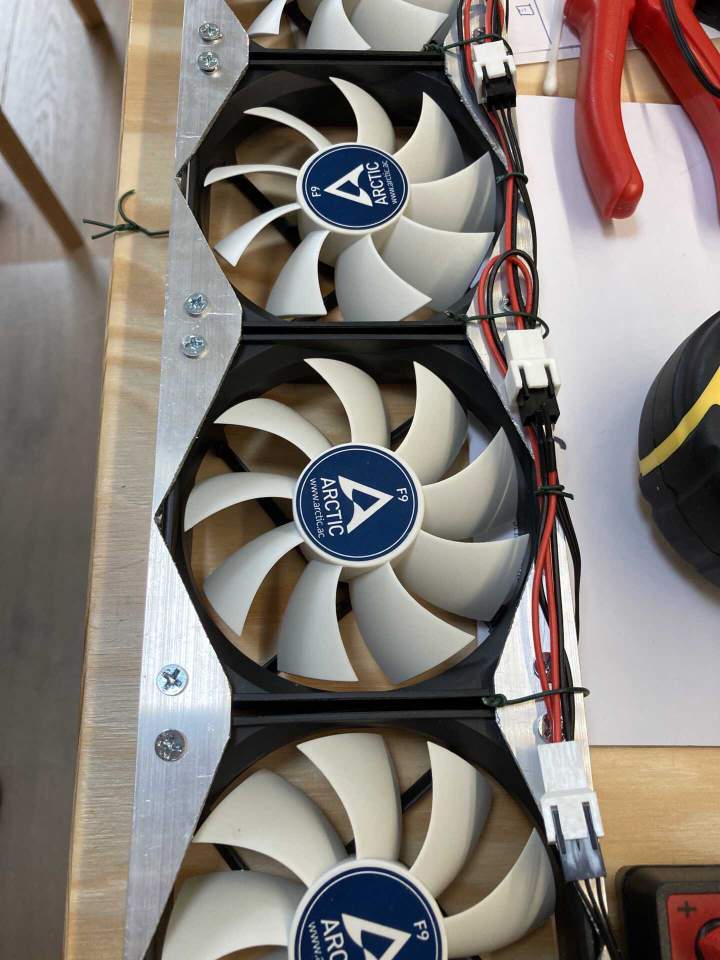

- 14x Arctic F9 fans (tweakers.net) (52€)

- 4m 20x20x2mm aluminium profiles (gamma.nl) (18€)

- 3x molex fan plug splitter (hardwarewebwinkel.nl) (12€)

- 1x XL4015 step-down converter (tinytronics.nl) (7€)

- 1x 12V >3A power supply, e.g. Seasonic SSA-0601HE-12 (tweakers.net) (20€)

- 1x Thermostat switch, e.g. this ready-made version (speedcomfort.nl), or solder one yourself

- 1x DC jack connector (tinytronics.nl), plastic is preferred for insulation

- Some power cable, I used 2x0.75mm^2 (gamma.nl) which might be a bit overkill but this saved me to investigate this (5€)

Total cost: 114€, plus shipping etc.

Fan throttling ¶

There are different methods to control fan speed (analog.com), e.g. using the fancy and optimal PWM, or using a blunt and simple voltage control. I settled for the latter for ease of use, as I can simple use a step-down converter (also called buck converter) to regulate my 12V input to anything from 0-12V.

Step-down requiremnets ¶

- Needs 17 * 2W = 35W @ 12V = 3A

- Efficient ideally >90%

- Accessible / easy voltage adjustment knob

Options:

- XL4015: 7 EUR, 96%, max 4A @ 32V, display. deltaU > 1.5V, Efficiency @ 12/5V * 5A = 87%

- XL4005: 3.5 EUR, 92%, max 5A @ 32V, needs cooling >25V. Efficiency @ 12/5V * 5A = 90%

- lm2596: 3 EUR, 92%, max 1A @ 35V, deltaU >1.5V.

- XL6009: 4 EUR, 94%, max 3A @ 32V, step up-down

Chose XL4015 because of high efficiency and display.

Fan requirement ¶

- Medium to high static pressure

- Low noise, <30 dB(A) at 10cm, preferably <20 dB(A)

- Low power, <1W per fan

- High MTBF, >100khrs

- Need low start-up voltage (e.g. able to run on at least 5V)

- PWM or ‘silent’ versions not required, simply under-volt.

Fans considered (see overview here (tweakers.net):

- Arctic F9 (tweakers.net): 4.0 EUR, 24dB, 60 m3/h, 1800 rpm, 1.35 mm H2O, fluid dynamic bearing, starting voltage: 2.6V, 1.9W

- Be quiet pure wings 2 92mm (tweakers.net): 9 EUR, 19dB, 56 m3/hr, 1900 rpm, rifle bearing @ 80khrs, 1.65 mm H2O, starting voltage 5V, 1.8W

- noiseblocker blacksilent xe-2 (tweakers.net), 8 EUR, 20dB, 65 m3/hr, 1800 rpm, 0.9 mm H2O, ?? Bearing @ 80 khrs, starting voltage 3.5V, 1.3W

- Enermax T.B.Silence 9cm (tweakers.net), 7 EUR, 13dB, 46 m3/hr, 1400 rpm, 1.2mm H20, twister bearing @ 160khrs, 1.8W,

I ordered each one of each, but did not notice too much of a difference in noise/airflow with an unscientific approach of listening by ear and feeling airflow with my hand. I therefore settled for the Arctic F9 fans for their low cost.

Temperature control ¶

I settled for a simple on/off thermostat which can switch my 12V input voltage. A more fancy control using temperature sensors, ESP8266, Wifi, MQTT etc. are all possible, which might provide slightly better performance, but I want my radiator to work when I turn the knob 🤓

Options found:

- Thermostaat 12v met schakelfunctie 10A (benselectronics.nl)

- Speedcomfort Thermostaatschakelaar (speedcomfort.nl)

I chose the Speedcomfort for my setup.

Power supply ¶

Requirements:

- High efficiency idle (<0.2W )

- Low noise, <30 dB(A) at 10cm, preferably <20 dB(A)

- Relatively high current (for worst-case 15 fans @ 0.2A we need 3A)

I had spare power supplies lying around, but else I would go for something from seasonic like this 60W Seasonic unit (tweakers.net). Unfortunately 3A @ 12V is slighly beyond the capabilities of adapter-type power supplies, so you get these brick-type supplies instead. Better safe than sorry.

Update: others do get away with a 3A 12V power adapter, so you might opt to use those. The advantage of a power brick is that you can position it away from a power socket, but of course it’s biger.

Construction considerations ¶

Fan frame ¶

I used aluminium profiles (20x20x2 mm^3) to hold the fans. This is light-weight yet sturdy, and relatively easy to saw/cut into shape yourself. For wider Jaga models (e.g. T20), you could use thin multiplex wood (e.g. 3.6mm) instead, which is slightly easier to saw/handle.

Optimal thermocouple positioning ¶

I tested a few locations to put the thermocouple, and in the end I compromised between optimal position (=fastest response) and accessibility (=easy monting). I mounted it on the pipes at the rear-end of the radiator. I tested the reponse and got the following results. It takes about 2-5 minutes after the central valve opens until the thermocouple is triggered. Not bad!

Timing:

- Evohome setpoint gateway to actuation: 2:30 min

- Actuation to return pipe temperature: 5:20 (1)

- Actuation to rear heat block temperature: 7:20 (2)

- Actuation to rear heat block pipe temperature: 7:20

Prototyping ¶

Before I made the above ‘industrialized’ version, I did some prototyping. Below a few pictures that might inspire others.